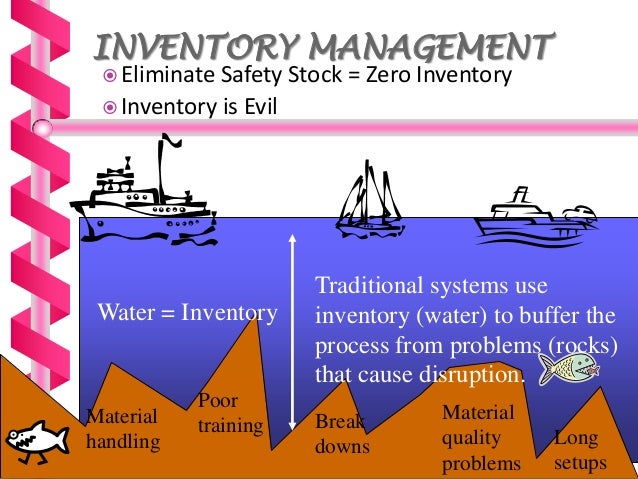

These inventory concepts help increase innovation while lowering costs and adopting new methods. Concepts such as JIT and lean manufacturing benefit in this effort.

JUST IN TIME INVENTORY MODEL HOW TO

Many employees who work directly in the process often have a better idea of how to remove waste in order to increase productivity and profit.īecause the manufacturing industry is highly competitive, organizations must be able to always improve and stay ahead. Manufacturers typically encourage all team members to contribute to lean methods in order to increase employee engagement. It is a strict mindset that encourages manufacturers to make cuts in areas they may not have thought of otherwise. Lean methodology considers waste to be any activity, process or product that does not create value for the customer. Manufacturers use these principles to optimize processes, improve productivity, cut costs and minimize waste. Lean manufacturing is the process of identifying areas that cause waste in resources and finding ways to eliminate them. Related: How To Perform a Risk Analysis How is JIT lean manufacturing? This helps manufacturers identify the limits of their work-in-process inventory to avoid overcapacity. Kanban was developed to improve efficiency by highlighting problem areas and measuring lead and cycle times. It is often used to supplement JIT and other lean manufacturing systems. Kanban is a scheduling system with origins in Japan that can reduce potential risks and increase benefits. Alternatively, an order may be placed by a customer that requires more materials than available. When manufacturers work with limited resources, a shipment delay could bring production to a halt. With all the good that a JIT system can bring to the production process, it is possible for them to disrupt the supply chain. New products are produced faster with greater ease than before, and space is no longer an issue because companies only order what they need for a specified time. Production costs fall, allowing funds to be better spent elsewhere.

Keeping production runs short: Since manufacturing companies know exactly how much they need to produce, the production time is much shorter.ĭecreasing required space for product: Without extra materials, manufacturers have additional warehouse space that they can eliminate or use for other means.

Keeping production costs low: Manufacturers buy only the materials needed for each order instead of purchasing an excess that they may not use. A JIT system, in particular, comes with a list of advantages, such as: The ability to streamline an internal system comes with benefits all its own.

For just-in-time to be effective, producers must be able to forecast potential demand with accuracy. The main benefit of this strategy is the reduced cost of inventory. Just-in-time receives goods only as they are needed for production, which increases efficiency and decreases waste. What is just-in-time inventory?Ī just-in-time inventory system is a strategy in which raw material orders from suppliers are aligned with production schedules. In this article, we discuss just-in-time as a system, weigh the benefits and risks and explore how it works in various manufacturing processes. JIT inventory is a type of lean manufacturing system that was developed to streamline processes and encourage innovation. The manufacturing industry can be competitive and costly, so many companies use just-in-time (JIT) inventory systems to manage expenses.

0 kommentar(er)

0 kommentar(er)